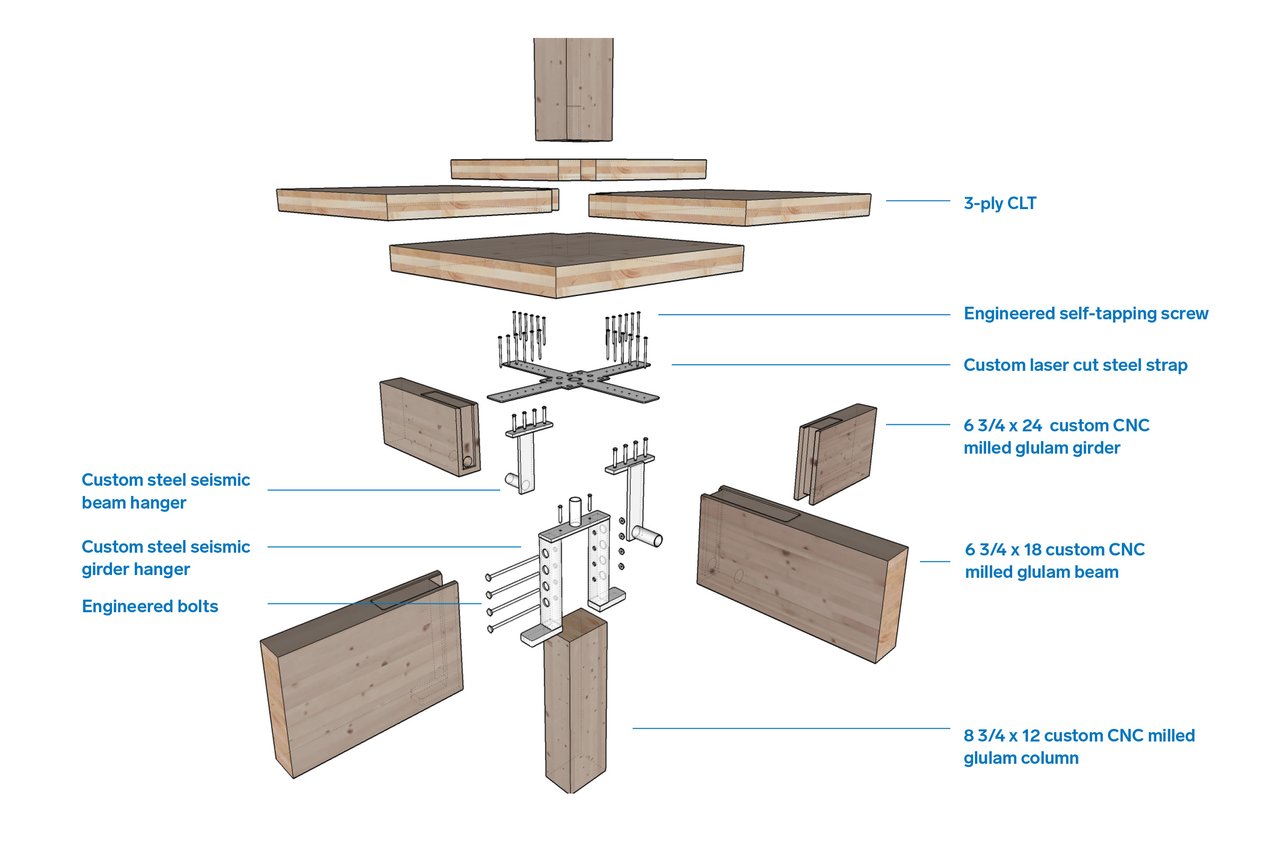

Collaboration is the most critical ingredient for innovation. To design, develop, and fabricate components that are novel or unique requires a precision that is only possible with a cross-disciplinary team. For Albina Yard, LEVER worked collaboratively with the project’s design-build team including the contractor, structural engineer, and fabricator to create the building’s mass timber connections. The glulam wood columns and beams were milled at CutMyTimber in Portland, Oregon, using a Hundegger K2 CNC joinery machine. The use of CAD/CAM software and CNC technology allowed the team to rapidly design and prototype precise connections, milled to an 1/8” tolerance. The team’s 3D model integrated the assembly’s concealed steel connections, which were also precision-fabricated at CutMyTimber.

Footage of a Hundegger K2 CNC machine custom milling the glulam beams used to construct Albina Yard.

Albina Yard's glulam wood columns and beams were custom milled at CutMyTimber in Portland, Oregon.

The precision modeling and fabrication included the project's custom steel connections.

Custom column, beam, and floor assembly