Albina Yard

Albina Yard is a new 16,000 sf speculative office building with ground floor retail located in North Portland. The building utilizes mass timber construction, with a glulam timber frame and Cross-Laminated Timber (CLT) panels manufactured and prefabricated in Riddle, Oregon. The project’s primary goal was to utilize domestic CLT in a market-rate office building that would pave the way for broader market adoption of renewable mass timber construction technologies in Portland and the US. The design approach reflects a commitment to this sustainable technology by developing an architecture focused on economy and simplicity, material expression, and the careful resolution and integration of all M/E/P building systems to foreground the beauty of the exposed Douglas fir structural frame.

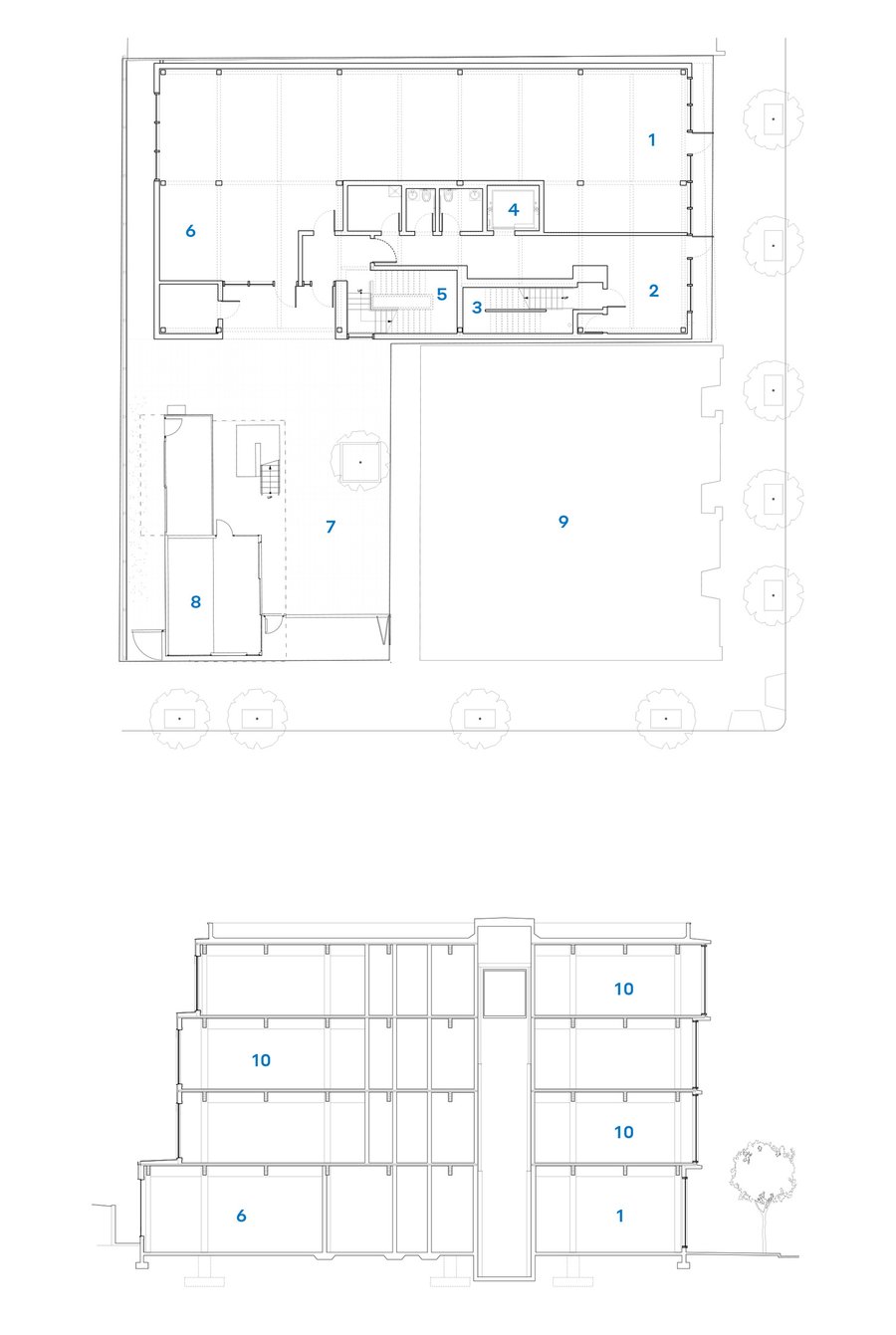

At the street level, the floor plan is organized around activating a small L-shaped infill site in a mixed residential/light industrial neighborhood. The side-loaded structural core connects the public entry to a day-lit CLT egress stair that opens onto a private south-facing courtyard. The retail space also connects to the street with a café/bar adjacent to the courtyard space. The upper floors have expansive views of Mt. Hood and downtown Portland, and are also divisible into four smaller units.

Albina Yard is made from an engineered wood product called Cross-Laminated Timber (CLT). The project is the first building in the US made from domestically-produced CLT.

The handrail in the central stair is made from three-ply CLT—the same ply thickness used for the building's roof and ceiling panels.

Site Plan and Section

Legend: 1 Retail; 2 Entry; 3 Egress Stair; 4 Elevator; 5 CLT Stair; 6 Cafe; 7 Courtyard; 8 Shipping Container/Office; 9 Neighboring Building; 10 Office