Mass Plywood Pavilion

Plywood has ancient origins—both the ancient Egyptians and Chinese developed ways of laminating pieces of wood together—but the production of the modern industrial material we know today began in 1905 at a plywood plant in Portland. Since that time plywood has become a ubiquitous part of wood construction throughout the world. Today plywood is widely used in low-rise wood construction. In the 1990s, companies in Austria and Germany developed a new type of cross-laminated wood panel (CLT) to enable construction of taller buildings. Due to the advantages of prefabrication and the low carbon footprint of building with a renewable resource, this new type of construction, collectively know as “mass timber,” is gaining traction globally. In the US, Oregon companies are leading the way to produce domestic versions of the product. In 2017, Freres Lumber began manufacturing a new product called “Mass Plywood,” which is made up of thin wood veneers. This pavilion is the first structure in the US built from this new mass plywood material with timber sourced from forests within 100 miles of the Freres’ manufacturing plant in Lyons, Oregon.

The Mass Plywood Pavilion was installed at the Portland Art Museum as part of the exhibition "Quest for Beauty: The Architecture, Landscapes, and Collections of John Yeon."

Mass Plywood Panel fabrication at Freres Lumber Co in Lyons, Oregon and installation of the pavilion at the Portland Art Museum.

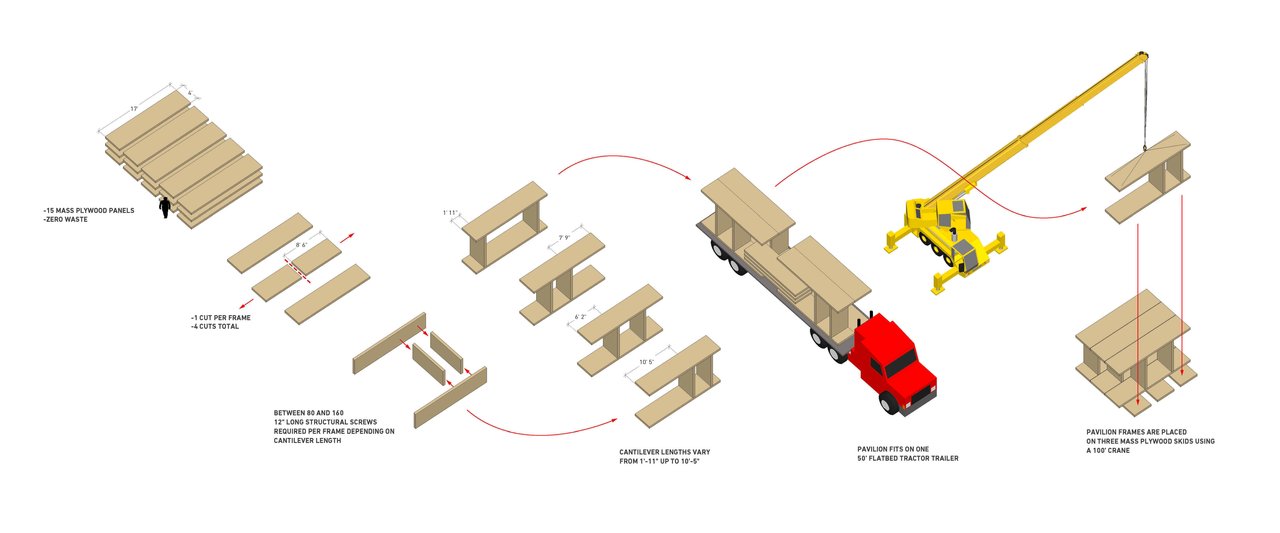

Construction Sequence

Each frame is structurally independent and was assembled using structural wood screws. A 100’ boom crane hoisted the four prefabricated frames directly from a 50’ semi truck into the sculpture court in 60 minutes.