Beginning in 2017, LEVER partnered with Freres Lumber Co and KPFF Consulting Engineers to explore the design and structural possibilities of Mass Plywood, a new veneer-based wood product developed by Freres Lumber with technical direction from the Tallwood Design Institute. Over the next few years, the team built three pavilions together to test the structural capabilities and manufacturing potential of the new material.

The first pavilion was on display at the Portland Art Museum during the summer of 2017, in conjunction with the exhibition, “Quest for Beauty: The Architecture, Landscapes, and Collections of John Yeon.” As the first structure ever made with this material, design and construction of the pavilion provided a unique opportunity to test the spanning, cantilevering, and structural connections for Mass Plywood.

The second rendition tested the production possibilities of Mass Plywood. On display at the 2018 Mass Timber Conference in Portland, OR, this was the first Mass Plywood structure to fully utilize digital fabrication technology.

The latest pavilion combines digital fabrication technology with skilled craftsmanship to celebrate the beautiful materiality of Mass Plywood. The structure was displayed at the 2019 Mass Timber Conference and at the grand opening of Oregon State University's College of Forestry’s A.A. "Red" Emmerson Advanced Wood Products Laboratory. This project is the first inhabitable structure to utilize 2” thick Mass Plywood.

For information on Mass Plywood Panels visit the Freres Lumber Co website.

Mass Plywood Panel fabrication at Freres Lumber Co in Lyons, Oregon and installation of the pavilion at the Portland Art Museum.

Mass Plywood Panel fabrication at Freres Lumber Co in Lyons, Oregon.

Mass Plywood is a large scale, structural panel made from wood veneers. This "super plywood" is available in thicknesses up to 24".

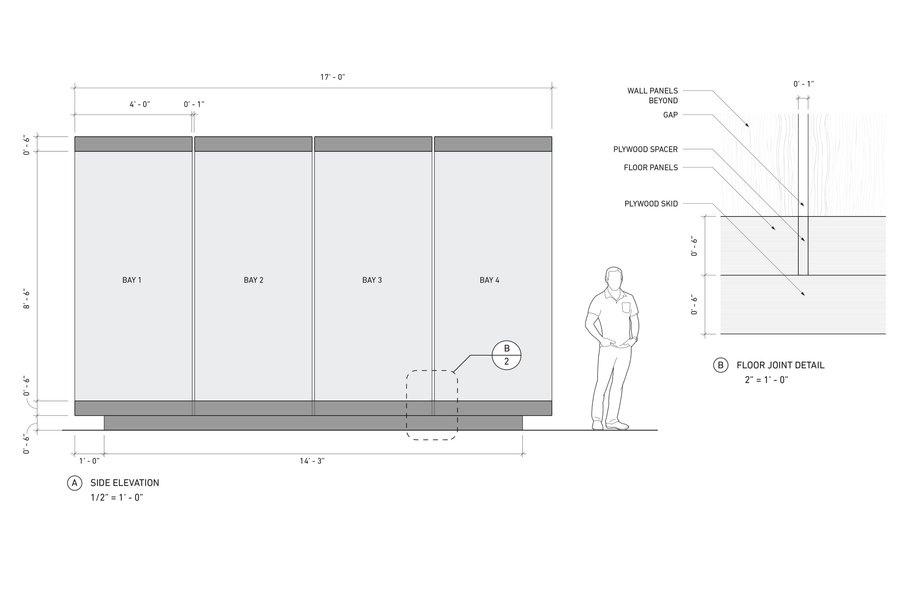

The final iteration of the first pavilion included 12' spans and a 10' cantilever. The team developed a construction scheme that included prefabrication of the four individual frames off-site and the craning in place and final assembly of the pavilion in the museum courtyard. The pavilion also provided the first opportunity to test how the material performed under the harsh environmental conditions of the Pacific Northwest.

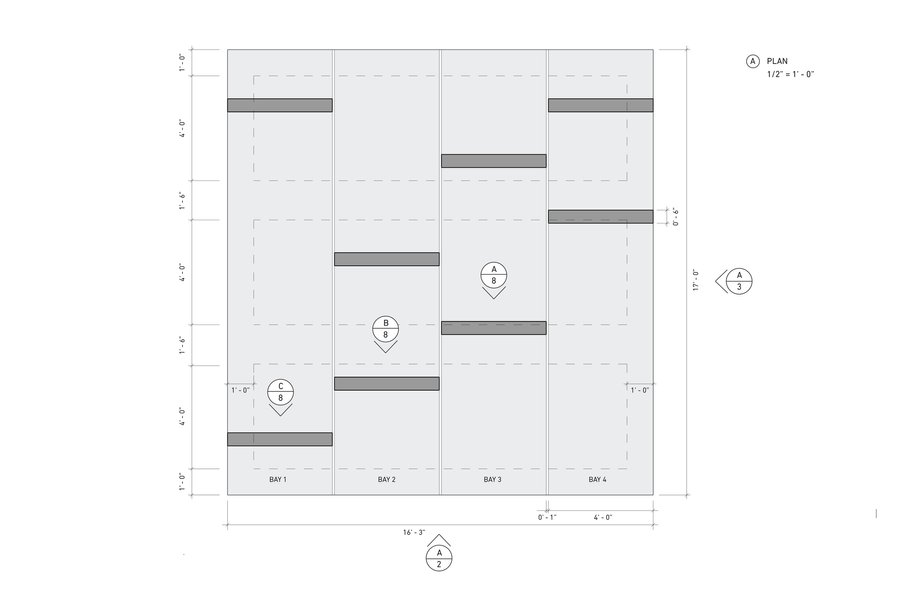

Plan and Elevation

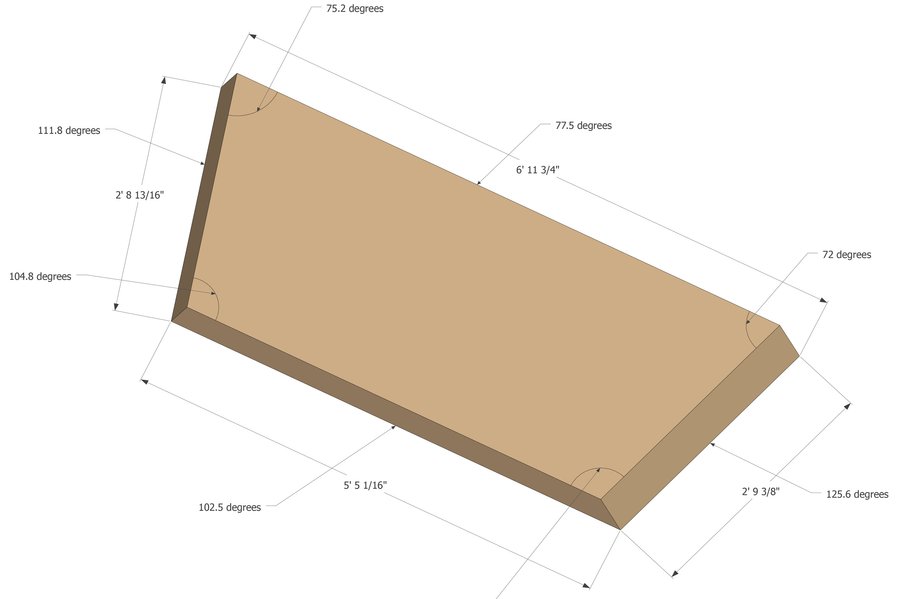

The design explores the spanning and cantilevering capabilities of a Mass Plywood Panel that is 4’ x 17’ x 6”. Each module used to build the pavilion is structurally independent.

Mass plywood panels prepped for assembly

Assembly of the 2019 pavilion structure to be displayed at the International Mass Timber Conference

The latest pavilion is the first inhabitable structure built with 2” thick mass plywood, and celebrates the beautiful materiality of this new product