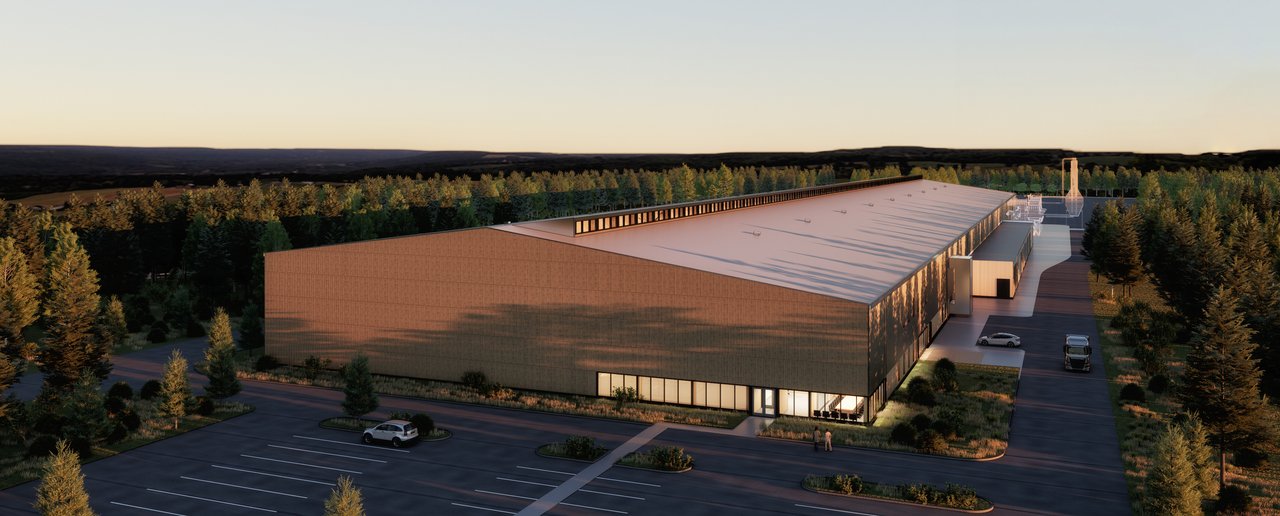

Timberlab Independence Hall

An industrial production facility for wood products which strengthens Oregon's mass timber supply chain, and an inspiring showcase that demonstrates mass timber's potential.

An asset to the regional supply chain, Timberlab Independence Hall is a Cross-Laminated Timber (CLT) manufacturing facility in the heart of the Pacific Northwest. When completed, it will stretch 190,000 sf, making it one of the largest CLT production sites in the country with an expected annual yield of 7 million to 9 million sf of CLT.

The facility will house large-scale manufacturing equipment for advanced timber and wood processing, including an automated feeding system, high-speed cross-cut saws and a top-of-the-line finger-jointing system.

Independence Hall houses state-of-the-art manufacturing equipment below long-span beams, allowing the unhindered movement of large CLT panels from lamstock, through manufacturing and fabrication, and onto trucks loaded inside the temperature- and humidity- controlled structure.

The design repeats a kit-of-parts bay structure over the length of the building, which takes advantage of economies of scale and simplifies installation.