University of Arkansas Anthony Timberlands Center

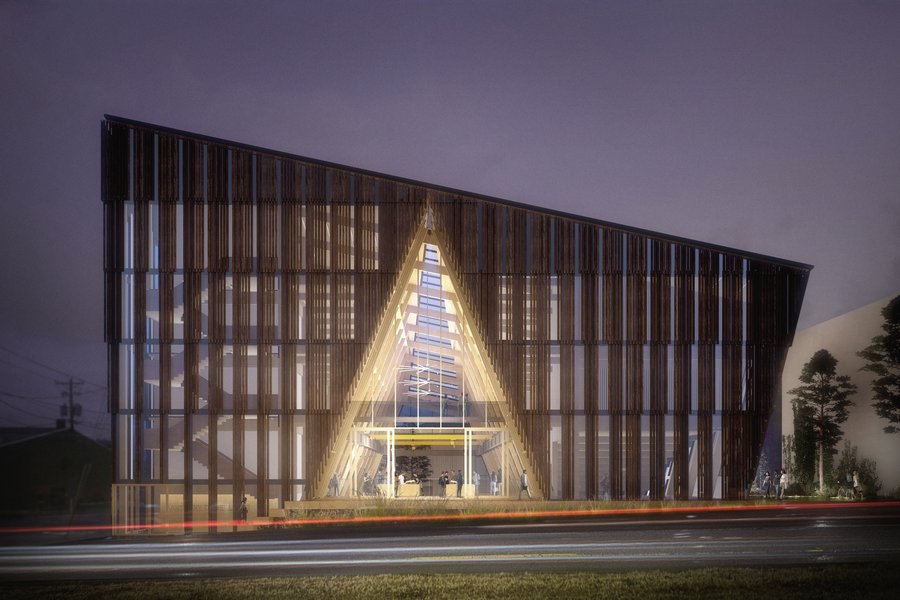

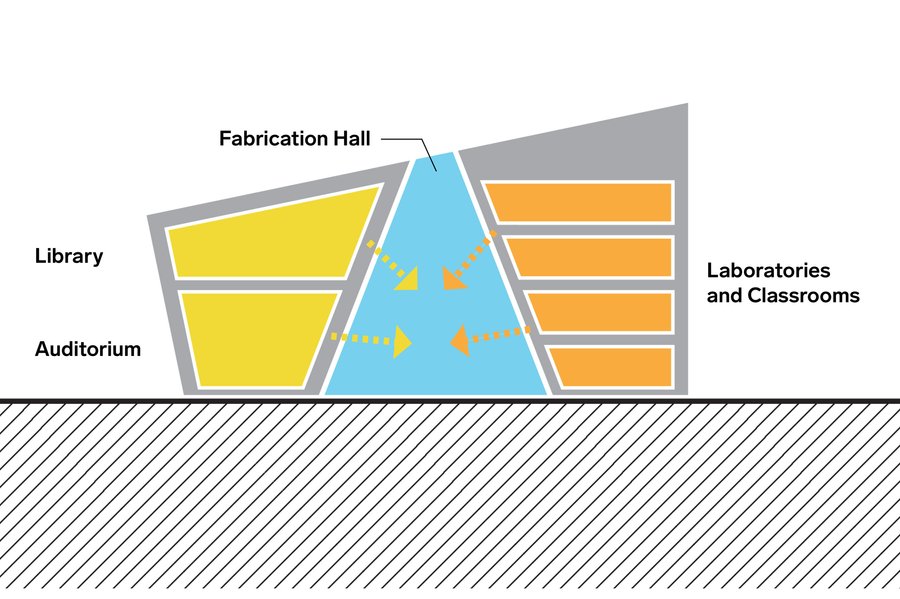

The Anthony Timberlands Center for Design and Materials Innovation is planned as an important extension of the University of Arkansas’ Fay Jones School of Architecture and Design. LEVER was selected to create a concept design for the project as part of an international design competition that included Dorte Mandrup, Grafton Architects, Kennedy and Violich Architecture, Shigeru Ban, and WT/GO Architecture. The Center is envisioned as a new applied research facility that will strengthen the School’s wood innovation initiatives and house its design-build program and fabrication labs.

LEVER's full design presentation is available for viewing here.

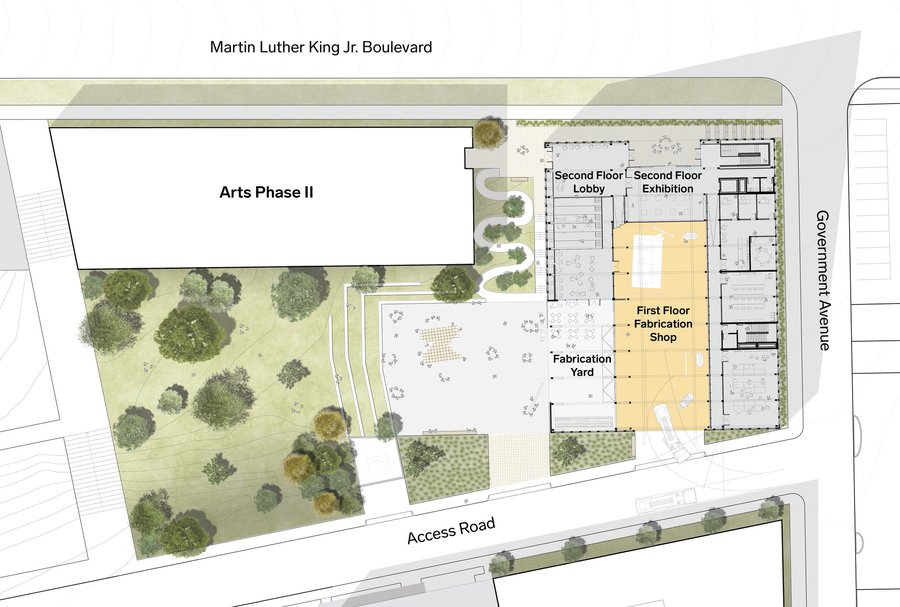

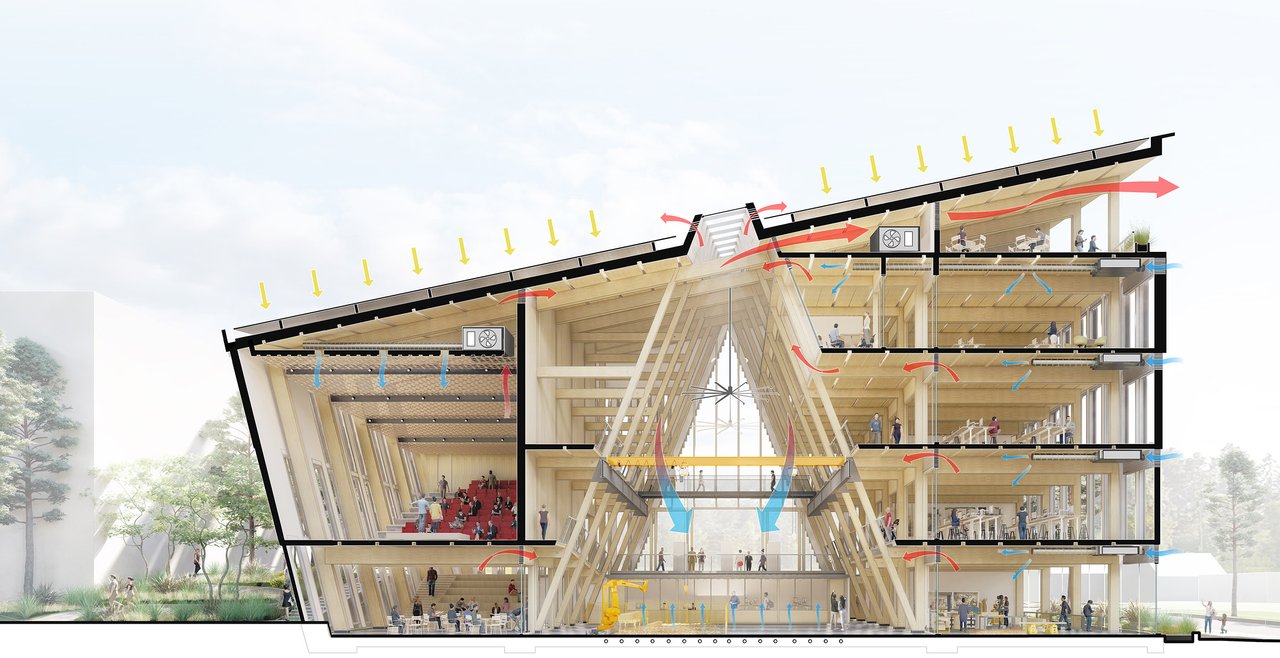

The fabrication hall opens onto a fabrication yard, café, and arboretum planted with tree species that represent Arkansas' working forests. The welcoming public spaces are intended to encourage interaction between the design and art schools.

Site Plan

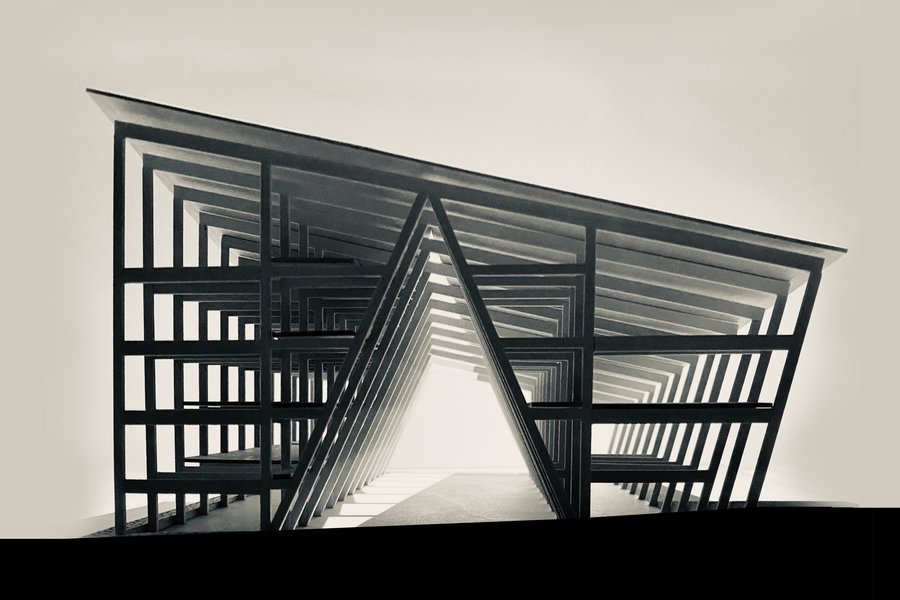

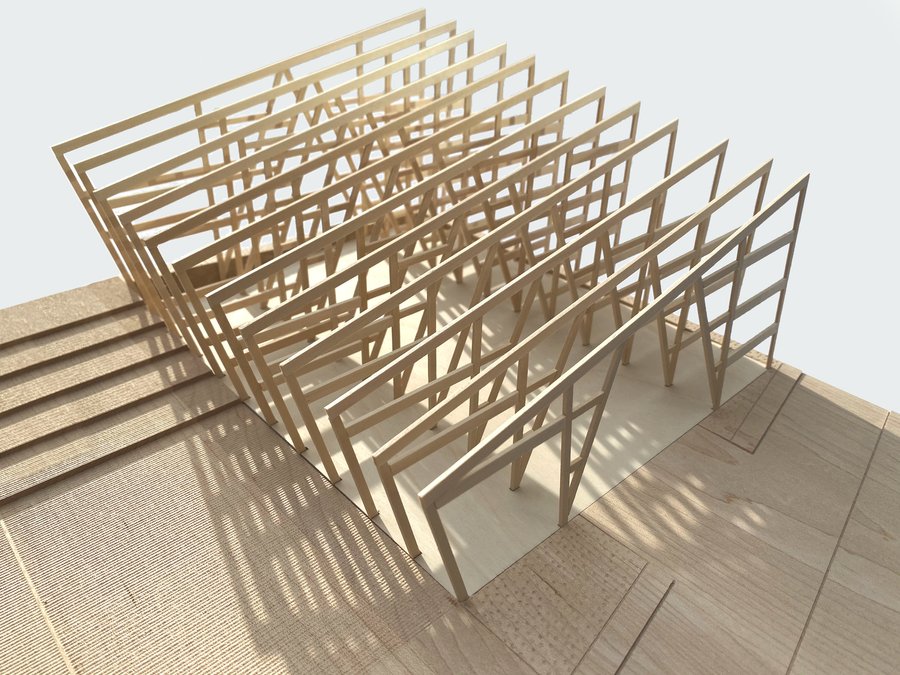

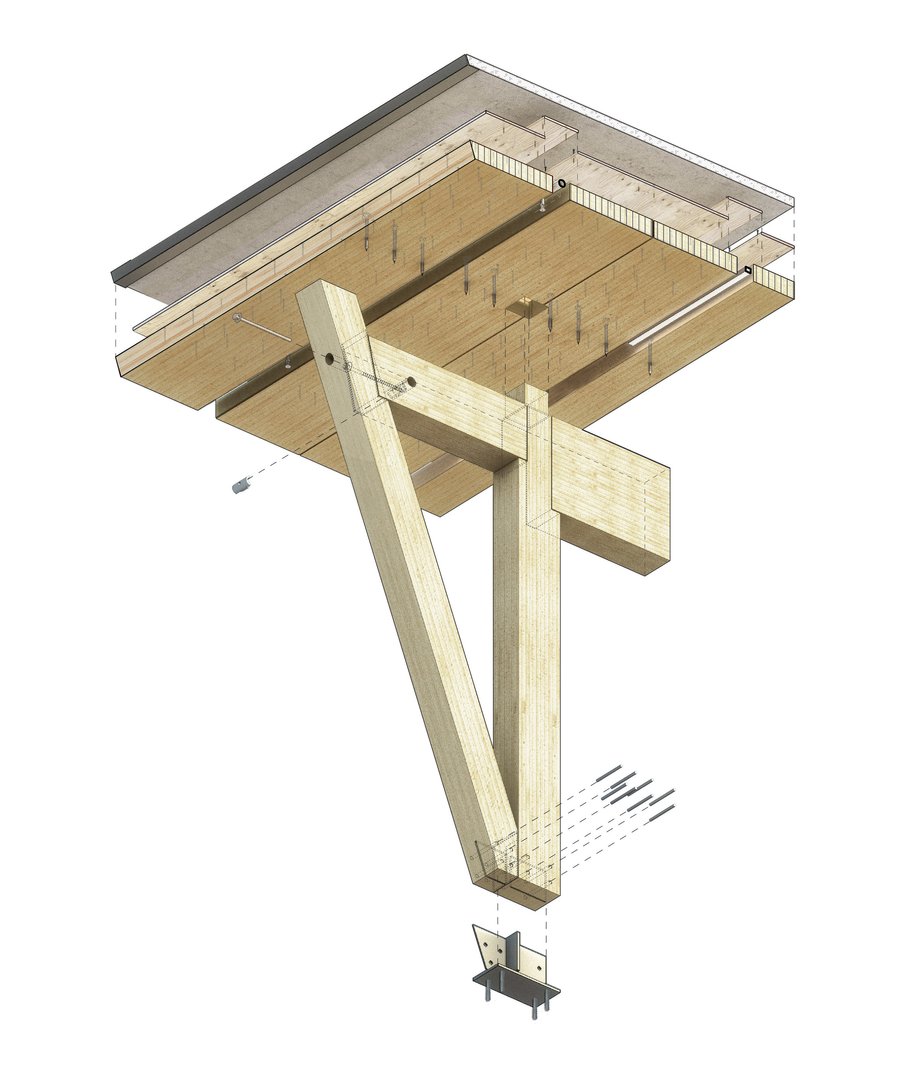

Structural mock-up fabrication at CutMyTimber

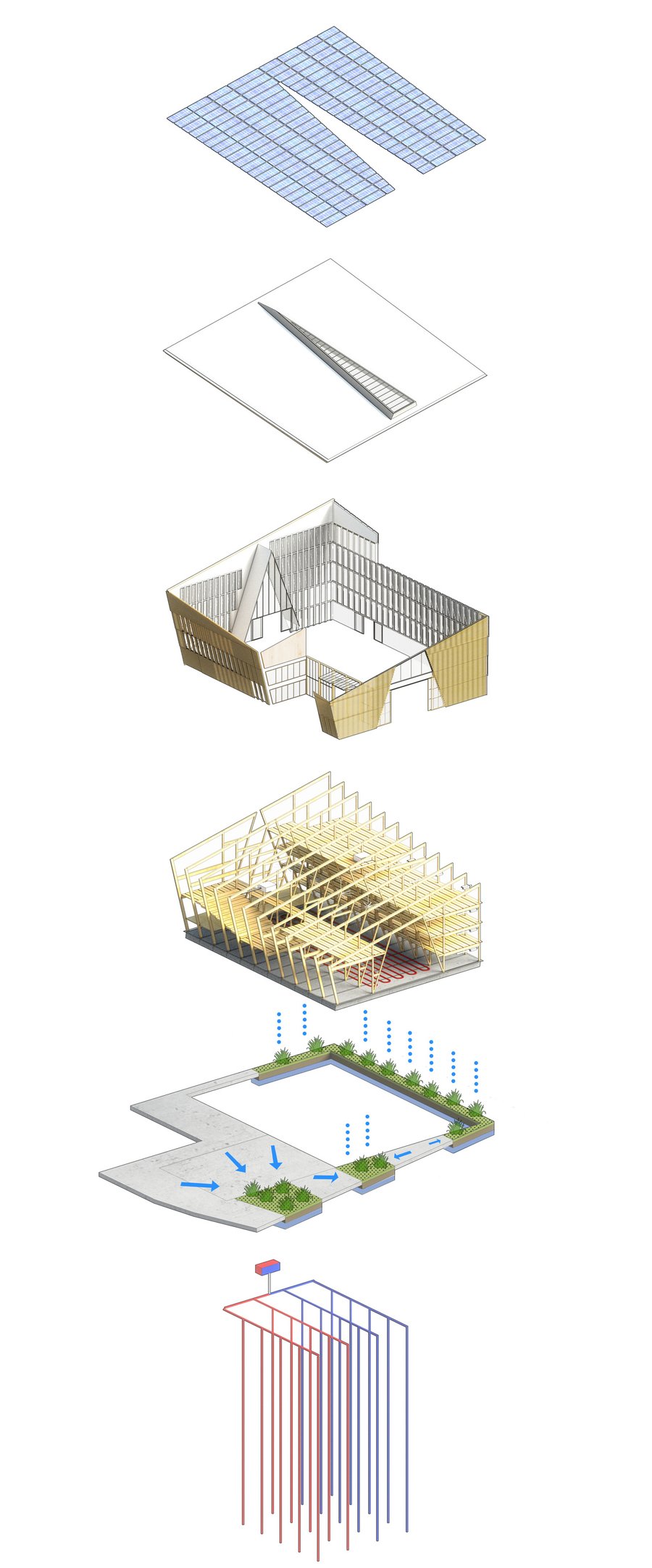

The design synthesizes passive strategies and active technologies into a sustainable whole. The landscape’s pervious surfaces, swales, and plantings manage stormwater, and its arboretum helps to cool the campus. The building’s massing, decentralized mechanical system, innovative heat recovery system, geothermal wells, and photovoltaic roof work in unison to harness the power of climate to manage and produce energy. An emphasis on responsibly-sourced, regional timber throughout the design dramatically reduces the project’s carbon footprint.

Mock-up building process at CutMyTimber