With an abundance of old growth timber present in the existing warehouses on site, the opportunity to incorporate salvaged timber into the design of Redfox Commons was enormous. Construction for this adaptive reuse project completed by LEVER in 2019 started with taking two World War II era warehouses down to their original heavy timber frames. In this process, the wood from an overbuilt mezzanine was deconstructed and salvaged to create a new entry between the two existing structures

The resulting volume and quality of salvaged lumber was exceptionally high, allowing for the wood to be repurposed for the structural frame, stair treads, and flooring of the new addition. Over 6,500 linear feet of 4x12 inch boards were reclaimed, varying in length from 12-24 feet. Working with the general contractor R&H Construction, the lumber was grouped and catalogued by length. From this stock list, LEVER created a diagram for the placement of the boards within the new entry.

The original heavy timber 4x12 inch boards were bundled and catalogued by length.

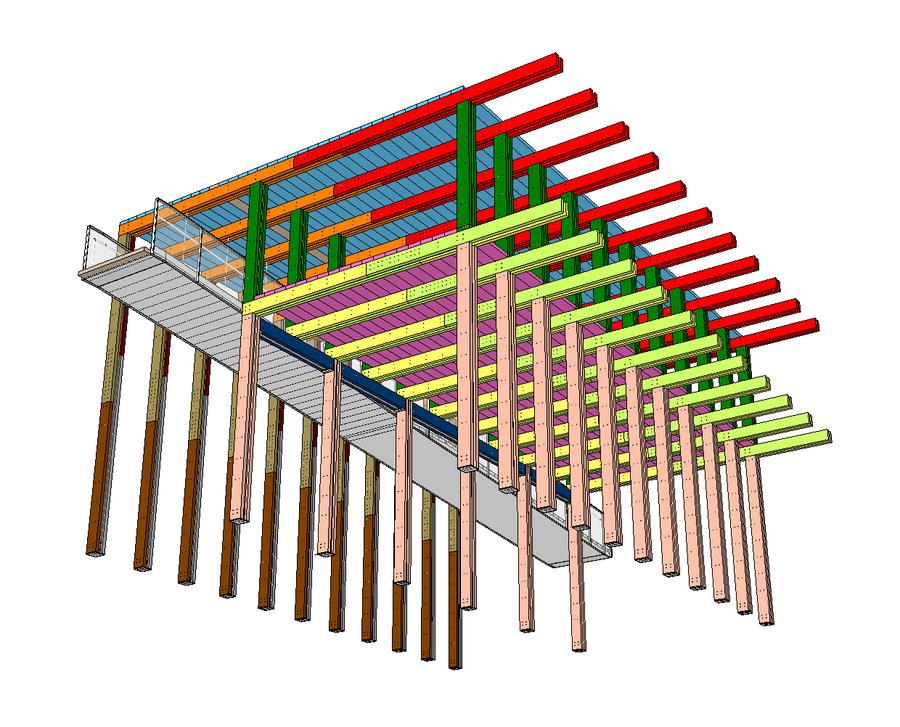

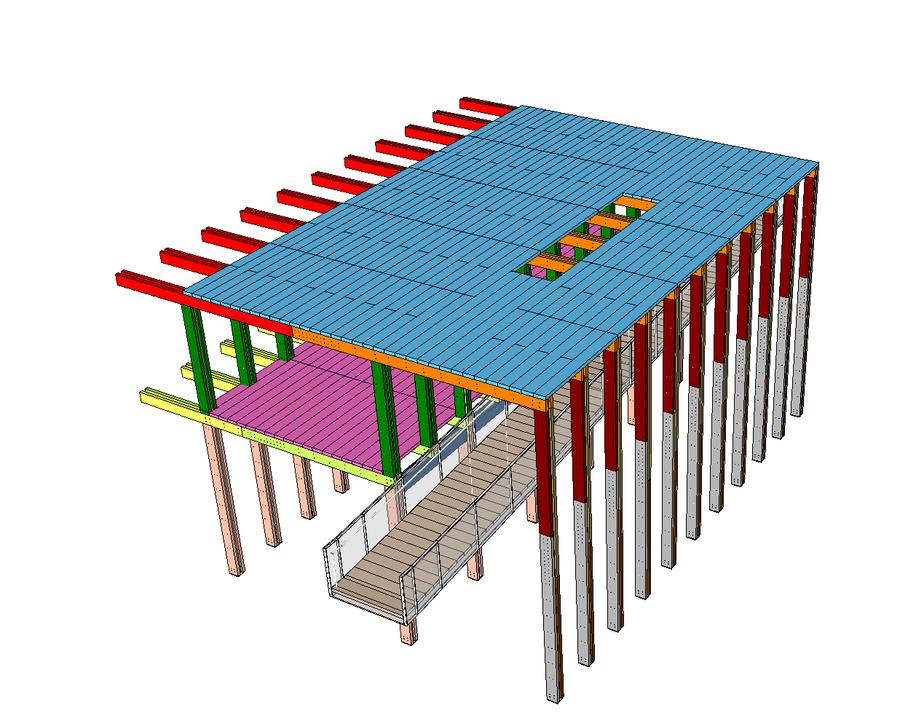

Each color on the diagram indicates a different board length to assist the contractor in the selection and placement of salvaged boards.

Screw-laminated timber columns bring together a mix of original heavy timber and new glue-laminated members to create a durable frame for the new entry.

The lumber was refinished using walnut shells in place of sand for a softer finish.

The new light-filled glass atrium built from salvaged lumber becomes the main entrance and connection between the two buildings.